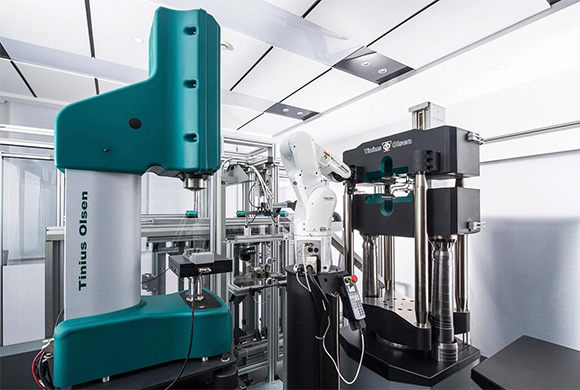

Material Testing Laboratory

Our global network of materials testing laboratories is dispersed over several locations. In order to evaluate the mechanical, physical, and chemical characteristics of materials as well as the quality control of materials and processes, these laboratories provide sophisticated characterisation testing.

We can contribute to all stages of the product life cycle, including development, manufacture, and in-service, thanks to our knowledge in this area. We deal with a broad range of industries, such as construction, machinery, oil and gas, 3D printing, automotive, rail, maritime, aerospace, and electrical and electronic products. We have extensive experience testing a wide range of materials, such as the following:

- Superalloys (titanium, aluminum, duplex, superduplex, inconel, etc.), metallic materials, and welded joints

- Glass and carbon fiber composite materials, as well as composite materials with fasteners

- Polymeric materials include rubber, thermosets, thermoplastics, and resins.

- Paints, varnishes, galvanized materials, and coatings

- Products and Materials for Construction

Among our testing competencies are:

- Production and setup of test specimens

- Mechanical tests, both static and dynamic (at temperatures ranging from -196 to +1200 deg C)

- Fractographic and metallographic examination

- Hardness tests (Vickers, Brinell, Rockwell, Shore)

- Chemical examination (XRF and OES)

- Thermal and physical testing (such as DSC, DMA, TGA, and FV)

- Non-invasive examinations

- Ageing and corrosion testing